![]()

Generation IV nuclear power plants are expected to provide greater efficiency in electricity generation and as a source for the large scale production of hydrogen while increasing the safety of the nuclear power plants. To accomplish this, the temperature of the plants needs to be increased from the 315°C of current pressurized water reactor designs to over 850°C. The materials currently used in coolant transfer applications are stainless steel alloys, which do not perform adequately at the higher temperatures required. Nickel-based superalloys, long developed for turbine applications, are noted for their strength and corrosion resistance at high temperatures. However, their corrosion properties are not well-defined for exposure to substances other than air. Potential coolant media in nuclear plants include molten salts, liquid metals, supercritical water, and helium gas. As corrosion is a limiting factor of the alloys in these applications, a more complete understanding of the corrosion processes is critical.

My research focuses on the corrosion properties of materials on a micro- and nano-scale. I am investigating solid solution strengthened nickel alloys, including Haynes 230, Inconel 617, Inconel 690 and Incolloy 800H. These alloys corrode via dealloying, a process by which extended high-temperature exposure causes chromium to form carbides along the grain boundary. This causes a local depletion of chromium near the grain boundary, lowering the resistance of the boundary to corrosion. Attack then proceeds along the depleted grain boundary through the alloy, causing corrosion further into the alloy than would general attack. While this model shows the overarching pattern of attack, the conditions close to the grain boundaries are unknown. A greater understanding of these conditions will allow for improvements in the life of the alloys and improved corrosion prevention measure to be found.

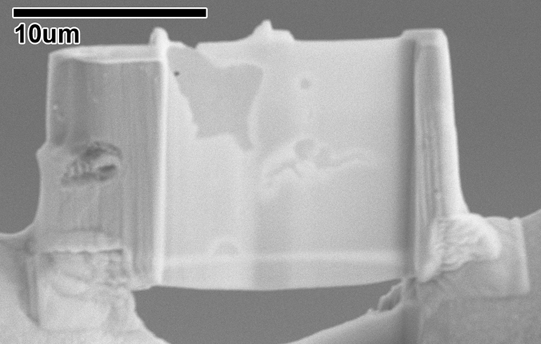

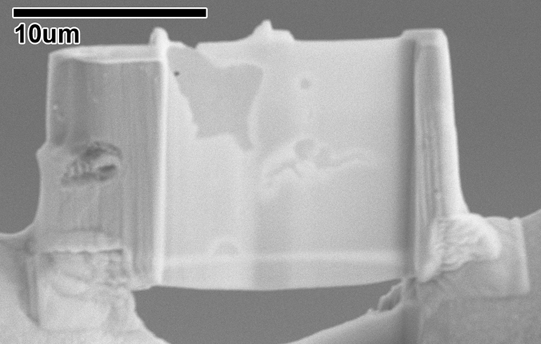

Figure 1. Using a Focused Ion Beam instrument I make TEM specimens from

specific locations in the sample to investigate the effects of corrosion

on different grain boundaries and at different depths within the sample.

Figure 1. Using a Focused Ion Beam instrument I make TEM specimens from

specific locations in the sample to investigate the effects of corrosion

on different grain boundaries and at different depths within the sample.

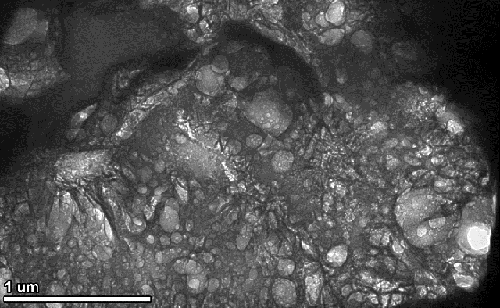

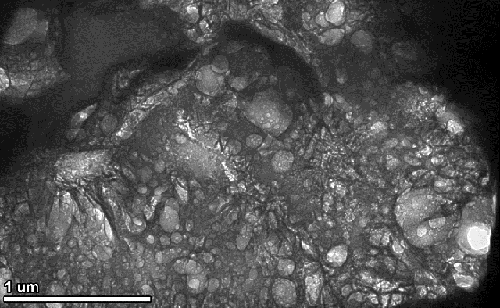

Figure 2. The high resolution of the TEM allows for a more precise characterization of the corrosion than conventional SEM and provides sub-surface information, as well.

My research focuses on the corrosion properties of materials on a micro- and nano-scale. I am investigating solid solution strengthened nickel alloys, including Haynes 230, Inconel 617, Inconel 690 and Incolloy 800H. These alloys corrode via dealloying, a process by which extended high-temperature exposure causes chromium to form carbides along the grain boundary. This causes a local depletion of chromium near the grain boundary, lowering the resistance of the boundary to corrosion. Attack then proceeds along the depleted grain boundary through the alloy, causing corrosion further into the alloy than would general attack. While this model shows the overarching pattern of attack, the conditions close to the grain boundaries are unknown. A greater understanding of these conditions will allow for improvements in the life of the alloys and improved corrosion prevention measure to be found.

Figure 1. Using a Focused Ion Beam instrument I make TEM specimens from

specific locations in the sample to investigate the effects of corrosion

on different grain boundaries and at different depths within the sample.

Figure 1. Using a Focused Ion Beam instrument I make TEM specimens from

specific locations in the sample to investigate the effects of corrosion

on different grain boundaries and at different depths within the sample.

Figure 2. The high resolution of the TEM allows for a more precise characterization of the corrosion than conventional SEM and provides sub-surface information, as well.

PhD Materials Science and Engineering

Previous Degree

Research Area 1

Research Area 2

Research Area 3

Research Area 2

Research Area 3